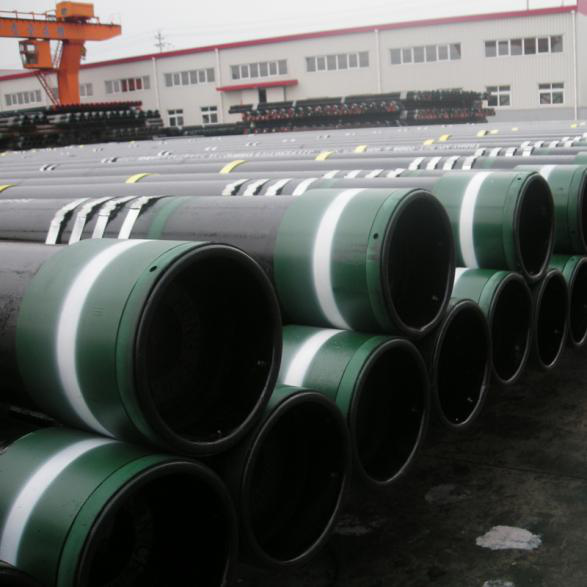

Technical process and precautions for short tubing connectio

When the oil pipe is in hot and cold weather, many pipe fittings of the vehicle can spontaneously ignite. If it is an oil pipe, aging and leakage will not only affect the normal operation of the vehicle, but also lead to the spontaneous combustion of the vehicle, which needs to be repaired as soon as possible.

After several years of use, it is often necessary to loosen the screws, which will inevitably happen to scratch. For example, the oil pan screws in the gearbox should be unscrewed each time the oil is changed. Before short-circuiting the pipe, wipe it with a dry cloth and the outside of the socket. When the surface is stuck, wipe it with acetone.

The short section of the tubing shall be smooth and the insertion mark shall be drawn before the short section and the test insertion shall be carried out.

The short connection of the pipe shall first release the parts connected to the pipe and then release the clamp holding the pipe to ensure that the metal cover of the pipe is properly connected to the joint of the connecting parts.

Connect the pipe to the assembly joint, then tighten the sensor screw with the tool belt, tighten the loose clamp on it, and apply torque three times to ensure good contact between the pipe and the assembly joint sealing surface.

In order to ensure the effectiveness of the construction time, the technical service department has carried out many times of verification and developed a new tubing short connection technology to perform pipeline short connection at the overflow point of the tubing. This process can be applied at room temperature without starting the fire. It is easy to operate and has the advantages of room temperature curing, simple process, convenient construction and fast curing time.