Briefly describe the machining optimization of tubing coupli

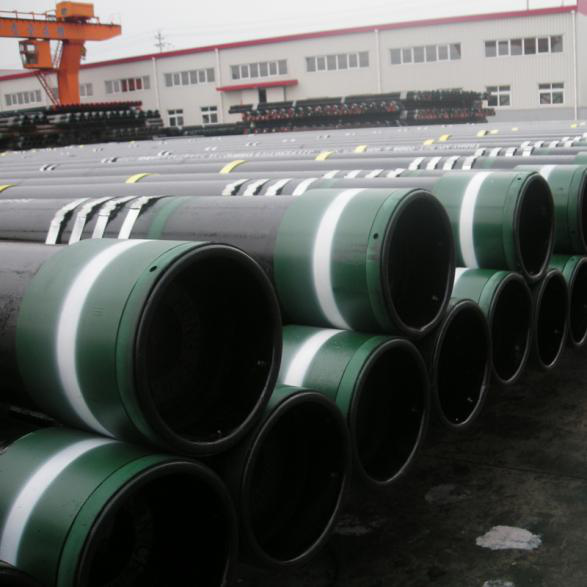

In the production of tubing coupling, both ends of the tubing need to be twisted and processed to make the internal thread at both ends of the coupling more uniform and the quality of the produced coupling better. In order to solve this problem, combined with the characteristics of machine tools, manufacturers have developed a set of simple structure, convenient and practical structure of the tool.

Prime minister, why is there a phenomenon that the tail end of the inner thread buckle at both ends of the collar is buckled randomly?

When the tubing coupling is machined, when the first head is machined and the second head is turned over, the starting point of the thread of the second head cannot be guaranteed to be within the same roundness of the first thread, and the blade fails after machining.

In the process, the distance from the origin of the first coupling to the end of the collet is longer than that of the second one. When the first head is finished, in order to ensure the size of the coupling length, the second head must be advanced in the negative direction by 1mm. In this way, even if the starting point of both ends of the thread is in the same Angle of the circle in the rotation direction, because of the coordinate offset, the two spirals will not be in the same spiral line, so the phenomenon of screw tightening still exists.

So what can be improved?

Make the 1.2-meter-high assembly platform first. The plane on the platform is welded by r die of 50mm wide 50mm high 50mm k40mm. It is used to secure the connector box and then a high pitch needle is made on the jaw plate at the same time using a hard alloy. A straight line perpendicular to the principal axis is drawn on the datum claw as the datum line.

Before processing, place the tubing coupling flat on the fixed channel steel of the tool platform, and draw the side bus with the needle as the marking line on the outer circle of the coupling. When clamping the coupling, the marking line on the outer circle of the coupling shall be aligned with the reference line on the base claw, and the head thread shall be processed. When turning the second end of the fixture, make sure that the marking line on the collar is aligned with the reference line on the claw. This ensures that the cutting point of the internal thread at both ends of the coupling is on the same dividing basis. The thinner the thread, the more accurate the alignment of the thread and the thread when clamping, and the higher the position accuracy of the connection between the two ends of the thread.

In order to keep the starting point of the thread of the second head of the coupling and the first "head screw outlet point" unchanged, the coordinate of the second head must be moved in a positive direction by 1mm, and the starting point of the thread cutter at both ends is equal to the length of the end face of the tool head. This solves the problem that the end of the inner thread of the coupling is buckled randomly. The resulting tubing coupling is of better quality.